产品型号:HQ-4

产品型号:HQ-4

更新时间:2025-07-01 08:58

更新时间:2025-07-01 08:58

厂商性质:生产厂家

厂商性质:生产厂家

访 问 量 :498

访 问 量 :498

185 7062 7934

机型型号:HQ-4

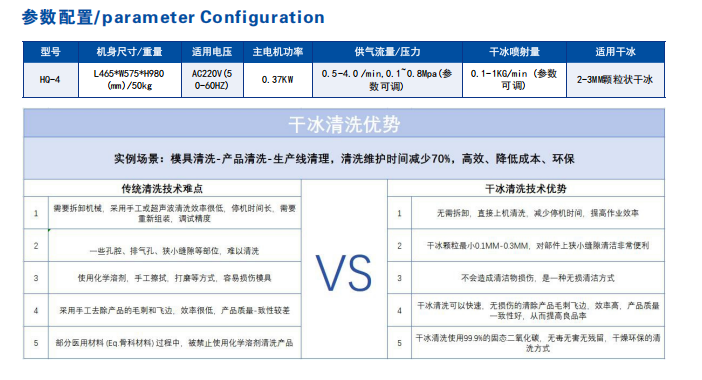

适用电压:AC220V(50-60HZ)

机身/重量: L465*W575*H980(MM)/50KG

主电机功率:0.25KW

供气流量/压力:0.5-4.0³/min /0.1~0.8Mpa(参数可调)

干冰喷射量:0.1-1.5Kg/min (参数可调)

适用干冰:2-3mm 颗粒干冰

料斗容量:20Kg

输冰管:4米GTL 1/2 低温干冰专用

高压气管:5米(1/2外牙接头&C型快插接头)

配套喷嘴

干冰清洗模具应用范围/Dry Ice Cleaning Mold Applications

适用于各类精密模具清洗维护(如注塑模具、硅橡胶模具, 压铸模具、发泡模具、冲压模具等),去除塑料残留、清洁排气槽和顶针、清洗油污残胶瓦斯气体,清洁模具花纹和沟槽,清洁细小型腔部 位,延长模具寿命,无需拆模卸模,停机直接清洗,洗完直接生产,提高作业效率 。

Suitable for all kinds of precision mold cleaning and maintenance (such as injection molds, silicone rubber molds, die-casting molds, foam molds, stamping molds, etc.), to remove plastic residues, clean exhaust grooves and ejector pins, cleaning oil residual rubber gas, cleaning mold patterns and grooves, cleaning small cavity parts, to prolong the life of the mold, without the need to dismantle the mold unloading molds, downtime, direct cleaning, washing directly after the production, to improve operational efficiency.

干冰清洗模具原理/Dry Ice Cleaning Mold Principle

1.低温脆化作用:温度差异导致污垢脆化干冰的温度极低,约 -78.5℃。当干冰颗粒与模具表面的污 垢接触时,污垢会迅速降温。污垢的物理性质在低温下会发生变化,变得脆硬易碎、更快地收缩,促使 污垢从模具表面剥离。

2.机械冲击效应:干冰颗粒的高速冲击在清洗过程中,干冰颗粒以高速喷射到模具表面。这些干冰 颗粒如同微小的子弹,当它们与污垢碰撞时,会在瞬间传递较大的动能,能够将污垢从模具表面直接击 碎并弹开。升华膨胀产生的推力干冰在接触污垢的瞬间会发生升华,从固态直接转变为气态。这一过程 体积会急剧膨胀近800倍。

3.热震效应:温度剧变引起污垢破裂当极冷的干冰颗粒与较热的污垢接触时,污垢内部会产生剧烈 的温度变化。这种温度差会导致污垢材料内部产生热应力,增强污垢与模具表面的分离,热震作用还会 使污垢与模具表面之间的连接界面受到破坏。原本紧密附着在模具表面的污垢,在热震的影响下,其与 模具表面的化学键或分子间作用力会被削弱。

1. Cold embrittlement: Temperature differences cause dirt to become brittle. Dry ice has an extremely low temperature of approximately -78.5°C. When dry ice particles come into contact with mold surfaces, the dirt cools down rapidly. The same is true when dry ice pellets come into contact with dirt on the mold surface. The dirt's physical properties change at low temperatures, becoming brittle, crumbly, and shrinking faster, causing the dirt to peel away from the mold surface.

2. Mechanical Impact Effect: High Speed Impact of Dry Ice PelletsDuring the cleaning process, dry ice pellets are sprayed at high speeds onto the mold surface. These dry ice particles are like tiny bullets. When they collide with the dirt, they instantly transfer a lot of energy. This can break the dirt from the surface of the mold and bounce away directly.Sublimation and Expansion Generate ThrustDry ice turns directly into gas as soon as it touches the dirt. This process makes the dirt volume get bigger by a factor of nearly 800.

3. Thermal Shock Effect: Dirt breaks apart due to extreme temperature changes.When extremely cold dry ice particles touch hotter dirt, the dirt undergoes a dramatic temperature change. This temperature difference creates thermal stress in the dirt, causing it to separate from the mold surface. The thermal shock effect also damages the connection between the dirt and the mold surface. The chemical bonds or forces that keep the dirt and mold surface attached are weakened by the thermal shock